- Full title Diseño y desarrollo, estructural y de sistemas, mediante el uso de herramientas CAD, FEA Y CFD, de un prototipo de draga ecológica para la limpieza por succión de fondos marinos

- Funding entity Centro para el Desarrollo Tecnológico Industrial (CDTI)

- Researchers Anne Gosset, Fernando López Peña, Vicente Díaz Casás, Marcos Lema Rodríguez

- Start date 02/01/2012

- End date 31/12/2014

- Website www.ecodraga.es

- Canlemar SL

- Centro de Investigacions Submarinas SL

- Nodosa SL

- Universidade da Coruña

Description

At critical points, dredging operations can generate turbidity; this project was conceived to find a joint solution to this problem.

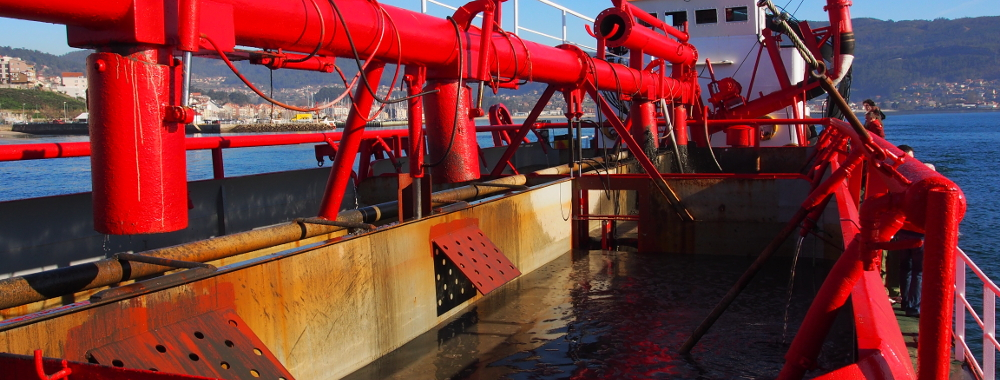

Its global objective was to design and develop an eco-dredging system. Of particular interest were systems used on seafloors covered with fine, contaminated sediments; these conditions are found both in coastal areas and river channels. A major concern here is that turbidity is produced and pollutants can be dispersed into the water column during dredging. There is overflow in the dredge’s hopper and sedimented material is discharged. With the new system, the environmental impact caused by this activity would be reduced.

The ECODRAGA system has been designed with three technical objectives in mind, to:

- Reduce the turbidity that is generated and increase the accuracy of dredging.

- Control water overflow in the hopper during the process of sedimentation.

- Manage dredged material so that it can be discharged in an environmental-friendly way. This is done by enclosing it within a geotextile bag.

Within the scope of this project, an existing dredger has been adapted so that the system could be installed and pilot testing could be carried out on an ECODRAGA prototype.

The GII took part in this project by designing the discharge system for dredged material by means of a fluid-dynamics study of the decantation with CFD methods.

Another role for the GII was to also participate in the design of the discharge process of the geotextile bag containing the sediments. We proposed ways of preventing excessive material from dispersing when the collection bag discharges from the hopper. A selection of these proposals was successfully tested on scale models and the actual prototype.

The GII was also in charge of designing the semi-closed circuit driving the water from the overflow back to the suction head. In this way, the recirculation of contaminants during dredging would be minimised.